Some of the die-cast joints used in the Insight's aluminum body are made using a newly developed casting technology invented by Honda engineers, called Thixotropic Die Casting. Thixotropic Die Casting uses aluminum alloy that has been heated to a semi-solid condition, instead of the molten, liquid state normally used in die casting. Pieces made with molten aluminum must be more highly processed and refined before casting; however, Thixotropic Die Casting requires less energy for smelting (an important consideration since aluminum is more expensive than steel), and owes much of its strength to the controlled formation of discrete aluminum crystals within the metal casting.

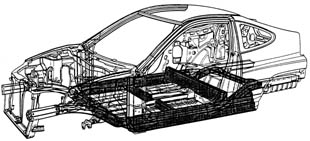

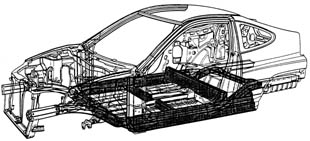

The Insight's aluminum body and frame are designed to meet the safety and impact-protection standards Honda engineers set for it. At the heart of this design is a newly developed Honda technology called G-Force Control Technology, or G-CON. G-CON optimizes each part of the Insight's aluminum body and frame to best absorb a specific type of impact. The cabin floor, for example, forms a strong and rigid foundation, designed to minimize deformation in an impact. Outside of this area, the surrounding aluminum frame members have been tailored to control impact forces.

Full-frontal and offset-frontal impacts are first absorbed by the large-section, hexagonal extrusions that serve as the front-side frame members. These hexagonal sections are made up of six individual equilateral triangles and are designed to progressively collapse like the bellows of an accordion in an impact. A die-cast aluminum joint connected to the rear of these extrusions transfers any additional impact energy rearward to an oval-shaped, curved hexagonal extrusion, which further absorbs energy by bending upward.

The aluminum extrusions that extend from the passenger compartment all the way back to the rear of the Insight on either side are also designed to progressively absorb rear-impact energy. In addition, the spare tire and wheel, and the Insight's aluminum suspension, including the tires and wheels, are designed to aid in rear-impact energy absorption.

Cabin deformation in a side impact is minimized by the Insight's highly rigid aluminum side pillar, side sill, rigid floor frame, floor crossmember and side-impact beams built into the doors.

Of particular note is the fact that Honda conducted impact testing on the Insight at higher speeds than that required to pass U.S., Japanese and European certification. Full frontal tests were conducted at 35 mph, offset-frontal tests at 40 mph, and side and rear tests were conducted at 31 mph.